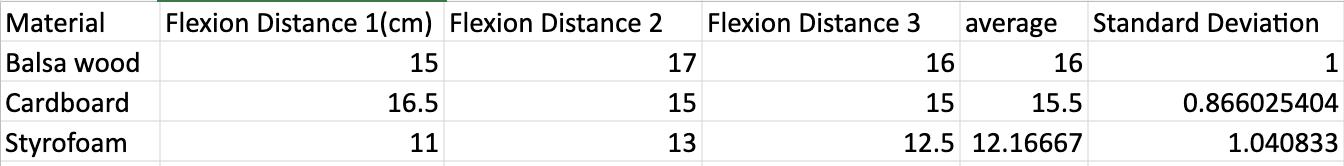

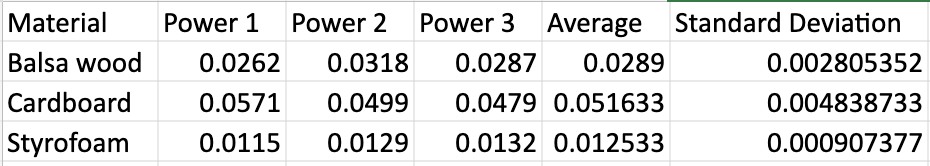

This experiment builds on the previous work done with our windmill kit. For this experiment we are focused on the construction of the blades. We want to find the optimal material between balsa wood, cardboard, and styrofoam. Our factors for considering the optimal blade material include power, which represents how effective the blades are, and flexion, which represents the durability of each material. These conclusions will allow us to construct a windmill that will provide the highest energy and durability through the optimum blade material.

Balsa wood or cardboard were considered for windmill blades. Consequently, balsa wood balances lightweight with a strength that can withstand all sorts of winds. On the other hand, cardboard is much heavier but delivers more power and still maintains some level of sturdiness. However, in spite of its low mass, styrofoam might not have the requisite robustness and propulsion capacity for efficient wind energy harvesting. Eventually, depending on the project details and some compromises between load-bearing capacity and force production potentialities, one may opt for either balsa wood or cardboard.

In conclusion, balsa wood, cardboard, and styrofoam have been tested for weight, density, power, flexion, and volume. Reviewing our data collected, cardboard produced the highest power rating of all the tested materials. The cardboard also did not break during the testing of flexion; it just bent back from the center. The cardboard that was tested was likely the most performant because it had the highest density and weight. The mass of the styrofoam does speak to the slower rotation rate. Balsa wood has been previously tested, and little change has occurred outside of increased speed due to angle rotation. Based on the data collected, we can conclude that cardboard is the most ideal material for our wind turbine systems.